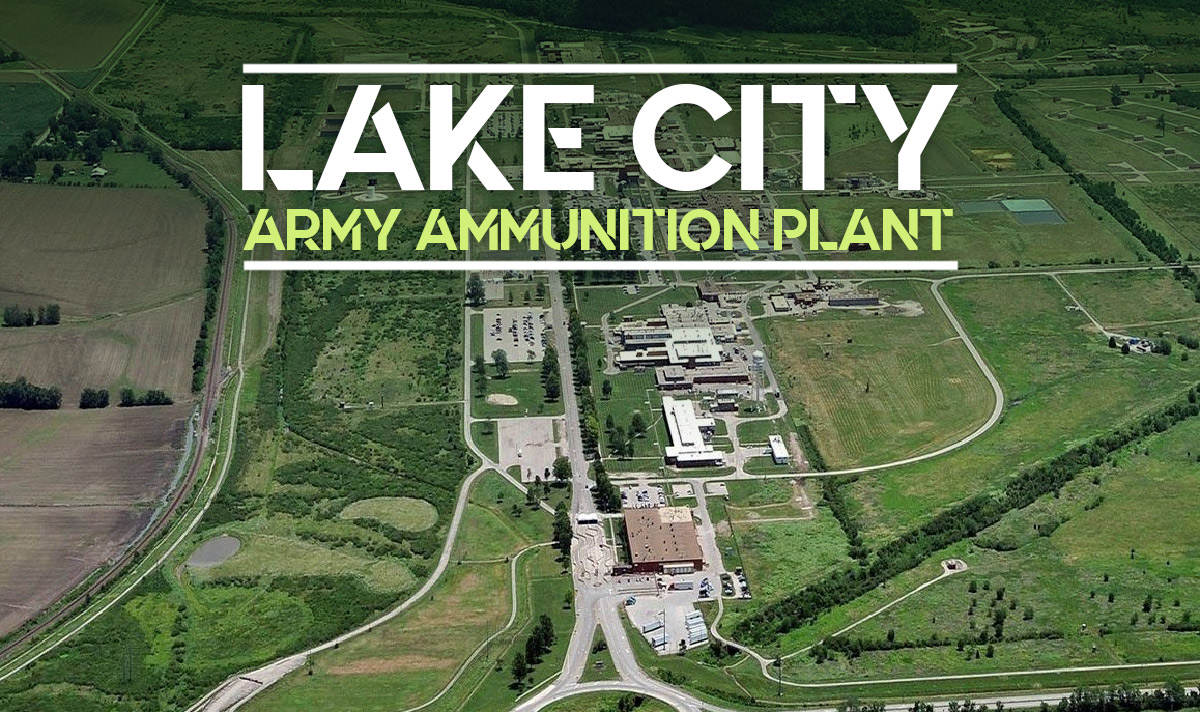

Have you ever wondered where your favorite high-quality ammunition comes from? Well, if you’re a gun enthusiast, it’s the Lake City Army Ammunition Plant (LCAAP). With its long and storied history stretching back over eighty years, this impressive factory has been the source of some of the most reliable ammo produced in modern times.

LCAAP has been quietly operating since 1941, when Remington Arms built it at the behest of the U.S. Army in Independence, Missouri, as a contingency for World War II. It quickly established itself as one of America’s premier ammunition production facilities. Over the years, LCAAP has supplied countless rounds of small and large-caliber military ammunition to U.S. troops worldwide, including in Afghanistan and Iraq.

So what makes this Southwestern Missouri plant so unique, and how did it become such an integral part of American history? In this blog post, we’ll take a look at the history and impact of LCAAP on gun culture over time – highlighting its rise from obscurity to distinction.

Lake City Army Ammunition Plant History

Workers on the Lake City Army Ammunition Plant assembly line during WWII. (Credit: Joint Munitions Command)

The Lake City Army Ammunition Plant has a rich history dating back to World War II. In the early 1940s, with the looming threat of global conflict, the U.S. government saw a pressing need for a significant boost in producing small-arms ammunition. Under the guidance of then-Senator Harry Truman, the US established the facility in 1941 to address this need. It covered an area of 3,935 acres with approximately 200 buildings, which today has grown to about 420.

The plant’s production output during the war was remarkable, reaching its peak in 1944 when it produced nearly 7 billion rounds of ammunition. After the war, the plant went through several periods of activity and inactivity, aligning with the needs of conflicts like the Korean War and the Vietnam War. The government reopened the plant during the Korean War and expanded to include a production line for .30 caliber ammunition.

Privatization

The LCAAP is the only active, government-owned, contractor-operated manufacturing facility for small arms ammunition. Apart from the 20-mm equipment installed after the Korean War and the revolutionary new SCAMP machinery introduced in the mid-70s, the LCAAP’s technology resembles World War II manufacturing practices. Although the plant retooled its existing .30-caliber lines for 5.56-mm and 7.62-mm ammunition, these modifications have not significantly altered the original production techniques. The plant’s original .50-caliber lines are virtually intact. These lines are the country’s only functional .50-caliber assemblage to survive the World War II era.

In 1985, the plant underwent a significant change. After operating LCAAP for more than forty-five years, Remington turned over operations. The U.S. government awarded a contract to the Olin Corporation (Winchester) to operate the plant, marking the first time they had entrusted a private company with the operation.

In 2001, Alliant Techsystems (now Northrop Grumman Innovation Systems) began operating the plant under the oversight of the U.S. Army. The ammo manufactured at Lake City during that time was sold under the Federal Ammunition brand. In 2018, Northrop Grumman (after the acquisition of Alliant Techsystems) expanded sales of ammunition made at Lake City to include Federal, Hornady, and Winchester brands.

In 2020, the Olin Corporation (Winchester) won the government contract again, and at the time of writing currently controls all LCAAP production. Commercially, ammo manufactured by Lake City wears the Winchester brand. Today, the LCAAP remains an essential provider of small-caliber ammunition to the U.S. military.

What is SCAMP Machinery at LCAAP?

SCAMP (Small Caliber Ammunition Modernization Program) in ammo production refers to a manufacturing process that utilizes automated machinery to produce small-caliber ammunition. This advanced technology increases manufacturing precision while significantly enhancing the efficiency and output rate. Initiated by the U.S. Army, the SCAMP revolution has dramatically improved the quality and quantity of ammunition.

What Types of Ammo Has LCAAP produced?

Lake City Head Stamp: The “LC” designates Lake City, the number is the year of production, and the circle markings indicate the case meets NATO standards.

Lake City Ammo, one of the nation’s leading ammunition manufacturers, offers a comprehensive range of products to meet diverse requirements. It’s been the birthplace of several types of ammunition renowned for their superior quality, reliability, and performance. From military-grade rounds to hunting cartridges, the production line at Lake City Ammo spans an extensive array of calibers and designs. The following include some of the ammunition Lake City produces:

- 5.56x45mm NATO: This cartridge is one of the most commonly produced ammunition at the Lake City Army Ammunition Plant. NATO forces and other military organizations worldwide widely use it.

- 7.62x51mm NATO: This is a powerful rifle cartridge used in various military weapons. Its production at Lake City ensures a steady supply for the U.S. military and allied forces.

- .50 BMG: The .50 Browning Machine Gun is a heavy machine gun cartridge produced exclusively at Lake City.

- .338 Lapua Magnum: Known for its long-range precision, the .338 Lapua Magnum is a favored choice among snipers.

- .300 Winchester Magnum: This is a popular round for big game hunting and long-range shooting. Lake City produces .300 Winchester Magnum ammo for military applications.

- .223 Remington: Similar to the 5.56x45mm NATO, the .223 Remington often appears in civilian and law enforcement applications. Lake City produces this cartridge in significant quantities.

- 6.8mm Remington SPC: Developed to improve the performance of the 5.56x45mm NATO cartridge. The military uses the 6.8mm Remington produced at the Lake City facility.

The Role Of Civilians in Ammo Production and National Security

The United States government contracts its ammunition production to private companies rather than manufacturing it internally. This approach leverages the efficiency and expertise of established industry professionals and helps stimulate the economy by providing jobs and supporting businesses. Furthermore, it enables the government to focus on its core responsibilities, such as defense strategy and policy-making, without the burden of operational complexities like ammunition production.

Unlike in many other countries, civilians play an essential role in national security, particularly in ammunition production. Under the guidance of governmental regulations, civilian industries manufacture ammunition critical to a nation’s defense forces. These industries also contribute to the advancement of ammunition technology, driving innovation to create more efficient and effective products. Civilian participation in this sector maintains a steady supply of ammunition, preparing the nation for any defense-related contingencies.

Market Shortages

It is generally agreed upon that LCAAP supplies about 30% of the commercial market’s 5.56x45mm NATO inventory. However, the Lake City production is first and foremost funneled to provide ammo to the US Army. Therefore as a military conflict arises, so do consumer fears that the government will require all ammo made at the plant. Historically, this scenario has created shortages in the commercial market.

In May 2016, the U.S. government placed a $210 million order with Alliant Techsystems to produce small-caliber ammunition for the U.S. Army. Five months later, in October, the government placed a second $126 million order for Non-U.S. standard ammunition. The LCAAP in Independence, Missouri produced and filled both orders.

Excess ammunition run during the production of military contracts becomes available to the commercial market. However, during the 2016 production run, there was no excess available to be sold. As a result, calibers such as 5.56x45mm NATO were extremely difficult to find that year creating demand that skyrocketed prices on the secondary market.

Lake City Army Ammunition Plant

Since 1941, the Lake City Army Ammunition Plant has produced munitions for the military and civilian market.

In conclusion, Lake City Ammo has consistently established prominence in the ammunition industry through years of delivering high-quality, reliable ammunition. Its commitment to manufacturing excellence and quality control measures ensure that every round of ammo meets military and civilian standards. These factors make it the top choice for gun enthusiasts and professional shooters alike.