Beretta history spans nearly 500 years, which makes it one of the most renowned firearms manufacturers and a cornerstone of the industry. Since its founding in 1526, this legendary Italian manufacturer has adapted to technological progress while keeping its dedication to consistent craftsmanship.

Beretta has made extensive contributions to military and civilian markets with its range of early black-powder weapons to contemporary firearms. The company led developments in firearm design engineering while helping create global safety standards. This article aims to tell the story of Beretta and how it became successful and remains relevant today in the firearm industry.

The Founding Father

Bartolomeo Beretta was an Italian artisan and maestro di canne–master gun barrel maker. Born in 1490, he worked as an ironmaster in the Gardone Val Trompia village, which was then part of the Republic of Venice. The area was known for its hills rich in iron ore and it became famous for iron smithing starting in the Middle Ages. The Beretta family has been working iron in the area since the 1400s.

In 1526, the Venetian Arsenal, a large-scale industrial enterprise in the region, paid Bartolomeo 296 ducats (approximately 1000 grams of fine gold) for 185 arquebus barrels. The arquebus was a heavy musket that required supports to fire. Since this is the oldest documented transaction, 1526 became the official start date of the Beretta company.

Beretta History: Surviving 19th Century Challenges

In the middle of the 18th century, the Beretta musket barrels lost popularity. In response, Beretta switched to different types of barrels and, in the early part of the 19th century, supplied barrels for a firearms factory in Brescia, a nearby city.

However, after Napoleon’s defeat in 1815, Beretta entered the Austrian military weaponry market. That same year, Pietro Antonia Beretta traveled around Italy, meeting various gun dealers and establishing business relationships that would enable the company to expand significantly in the 19th century.

In 1832, Pietro officially named the manufacturing firm Fabbrica d’Armi Pietro Beretta, which it still uses today. Pietro passed the company on to his son, Giuseppe, who continued his father’s work by traveling through Europe to create more business connections.

Giuseppe also pushed the company into creating whole guns, not just barrels, for the first time. Although the previous focus had been on military weaponry, Giuseppe identified the value of civilian sporting firearms.

Under Giuseppe’s leadership, the firm began to expand. For instance, in the mid-1880s, Beretta produced around 300 guns annually. However, under Guiseppe’s oversight, Beretta produced 8,000 guns in 1880 alone.

The company’s popularity soared, and in 1899, Giuseppe had the Beretta Hotel built in Gardone for international visitors to the firm’s factory.

Key Innovations: Beretta Family

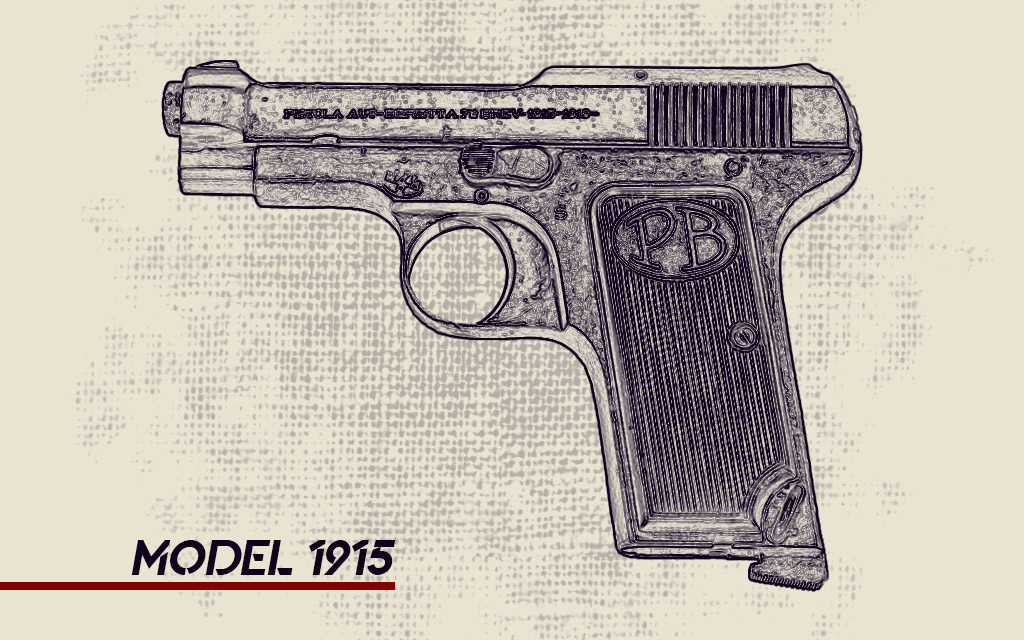

Origin Story: The Beretta Model 15 pistol was the first semi-automatic pistol manufactured by the company.

In addition to the arquebus barrels, the Beretta family has introduced numerous innovations in firearm manufacturing throughout their long history. Here are some of the most significant contributions:

Beretta Model 1915

The Beretta Model 1915 was a significant milestone in Beretta’s history as their first semi-automatic pistol. It was designed by Tullio Marengoni, the company’s chief engineer, to replace the complex and weak Glisenti Model 1910. Here are the key features and developments of this innovative firearm:

Design & Specifications

- Action: Simple blowback, single action with an internal hammer

- Caliber: 9mm Glisenti (original model)

- Capacity: 7 rounds

- Weight: 29.75 oz (empty)

- Length: 6.7 inches

- Barrel length: 3.7 inches

The Model 1915 featured an open slide design with an exposed barrel that became a signature design for future Beretta pistols. It incorporated two manual safeties – one on the left side of the frame blocking the trigger and another on the rear of the slide, locking the hammer.

The Royal Italian Army adopted the Model 1915 during World War I, and some of these pistols remained in use until the end of World War II in 1945. Beretta produced approximately 15,600 units between 1915-1918.

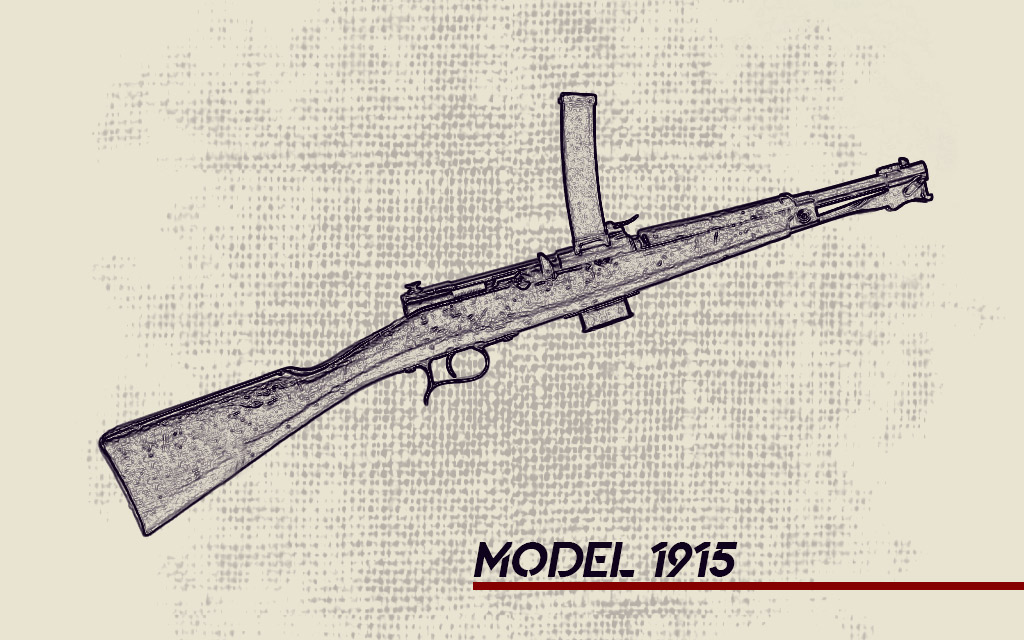

Beretta History: The “Automatic Musket”

Moschetto Automatico: The Beretta Model 18 rifle was a self-loading carbine that saw action in WWI.

The Beretta Model 1918 was one of the earliest submachine guns developed. It saw combat in the final months of World War I, and this innovative firearm significantly influenced the evolution of automatic weapons.

The Model 1918 was derived from the Villar Perosa, a twin-barreled aircraft machine gun, and its features included:

- Action: Simple blowback

- Caliber: 9mm Glisenti

- Magazine Capacity: 25 rounds

- Rate of Fire: 900 rounds per minute

- Barrel Length: 12.5 inches (318 mm)

The weapon featured an unconventional top-loading magazine and a folding spike bayonet. Some records suggest the Model 1918 saw combat a few weeks before the German MP-18, making it the first submachine gun to see combat.

The Model 1918 later influenced Beretta designs, including the Model 38 series, which became the standard Italian submachine gun in World War II.

Modern Manufacturing Techniques

As the twentieth century began, Beretta entered a period of modernization, thanks to the efforts of Pietro Beretta (1870-1957). The turn of the century marked a turning point for the company, which had 130 employees.

Pietro established a hydroelectric plant on the Mella River to provide the factory with its power source, reducing reliance on public utilities. He introduced advanced production techniques and patented numerous machines and parts, demonstrating a commitment to technological innovation.

Under Pietro’s leadership, the company grew from a single 10,000-square-foot factory to 75,000 square feet, employing 1,500 workers by the end of the century.

Known to be intelligent, intuitive, and charismatic, Pietro Beretta introduced the most modern machining systems. He created innovative products, such as those mentioned above: the first semi-automatic pistol, the 9mm Glisenti Model 1915, and one of the first machine guns, the Model 1918, dubbed the “Automatic Musket.”

Beretta History: Post-World War II Developments

After World War II, Beretta continued to innovate and expand its firearm production. Here are some notable post-war developments:

Military Adaptations

Beretta repaired American M1 Garands that were given to Italy and modified them into the Beretta BM-59 rifle. Under certain conditions, many considered this rifle superior to the M14 battle rifle in terms of accuracy.

Civilian Market Expansion

Beretta resumed production of the high-end Sovrapposti over/under shotgun, which was introduced in 1935 but interrupted by WWII. The company continued developing firearms for military and civilian markets.

International Growth

In the 1970s, Beretta established a manufacturing plant in São Paulo, Brazil, which produced Beretta 92s for the Brazilian army until 1980. In the late 1980s, it acquired several domestic competitors (including Benelli and Franchi) and some foreign companies.

Significant Products: Beretta History

The Beretta M9 (Model 92FS) served as the U.S. military’s service pistol from 1985-2017, although many remain in use.

The Model 92 was developed through various iterations (92S, 92SB, 92F, 92FS), culminating in its selection as the U.S. military’s service handgun from 1985 to 2017 and designated the M9 pistol.

Technological Advancements Across Beretta’s History

- Modular Designs: Beretta pioneered advanced modular firearm designs.

- Polymer-Framed Pistols: They introduced the PX4 series, incorporating polymer frames.

- Gas-operated semi-automatic shotguns: The 1301 series was introduced in 2014.

- OptimaBore Technology: The company developed this technology to improve the accuracy of shotguns.

These developments showcase Beretta’s ability to adapt to changing market demands and technological advancements in the post-war era, solidifying its position as a leading firearms manufacturer.

Beretta History: Modern Manufacturing

Over the years, Beretta has consistently embraced modern manufacturing techniques to maintain its position as a leader in firearm production. The company’s commitment to innovation is evident in its advanced manufacturing processes and technologies:

U.S.-Based Facilities

In 2016, Beretta moved their manufacturing operations in Accokeek, Maryland, to a new facility in Gallatin, Tennessee. The new plant covers 160,000 square feet on a 100-acre plot, and is home to all manufacturing operations for Beretta USA. The Gallatin facility not only provides state-of-the-art facilities to meet demand, but also supplies them room to grow in the future.

Automated Manufacturing

Beretta extensively uses CNC (Computer Numerical Control) machines to produce its firearms. By incorporating CNC technology into its production processes, the company has significantly enhanced its manufacturing capabilities, allowing for increased precision, efficiency, and output in firearm production.

The company also utilizes robotic measuring equipment capable of measurements within ten-thousandths of a millimeter, ensuring tight tolerances across all its products.

Advanced Technologies

Beretta has developed several proprietary technologies to enhance firearm performance:

- Steelium®: An innovative barrel production process that transforms premium steel into high-performance barrels, offering exceptional precision and durability.

- OptimaBore® HP: Advanced barrel technology designed to optimize shot distribution and reduce recoil.

- B-Link®: A system for semi-automatic shotguns that reduces the operating cycle and improves reliability.

Research & Development

Beretta’s R&D plays a central role in innovation:

- In-House Processes: All research and development activities, from design to prototype testing, are conducted internally.

- Advanced Design Systems: The company uses sophisticated computerized design and simulation systems.

- Additive Manufacturing: Beretta uses 3D printing techniques for prototyping and production.

Quality Control & Testing

Beretta employs cutting-edge methods for quality assurance:

- Laboratories have advanced systems for metallographic analysis and fatigue testing.

- Recoil Analysis: The company has developed a recoil recorder that uses electronic impact pads to gather data to improve its shotgun design.

- Artificial Limbs: Sophisticated sensor-equipped artificial limbs test short arms and gather usage data.

Effecient Manufacturing

The company implements lean and Six Sigma methodologies:

- Kanban: Used for inventory management and production flow.

- Process Mapping: Employed to improve operational efficiency.

- ISO 9001 Certification: Beretta’s U.S. operations are certified, ensuring consistent quality standards.

These manufacturing techniques have allowed Beretta to maintain its reputation for quality while increasing production efficiency and innovation in firearm design and performance.

Beretta History: Legacy of Innovation

Beretta’s legacy speaks to its relentless pursuit of innovation, quality, and craftsmanship.

Beretta’s longevity testifies to the company’s relentless pursuit of innovation, quality, and craftsmanship, which created its leading position in the firearms industry. For almost five centuries, the company has adjusted to technological innovations and changing market requirements, thus establishing itself as a leading global force.

Beretta’s products, which now operate globally, have inspired military tactics, sporting customs, and industrial specifications. The company continues to advance into new technologies while respecting its historical tradition for tomorrow. Through its story, the company showcases historical evolution and current progress in firearm manufacturing.