You’re out at the range, about to run the first magazine through your new AR-15. You pull the charging handle, drop the bolt, turn off the safety, and BANG! The first shot rings out. Your AR-15 ejection patterns send the brass casing sailing through the air, landing on your neckline and sliding down your shirt.

Now, what should have been your moment of glory is now a viral internet moment. You dance around desperately, trying to get the hot brass off your skin while your friends enjoy a good laugh at your expense. So what went wrong? There’s a strong chance your new rifle is short stroking, so the ejection pattern sent the brass in the wrong direction.

Your AR-15 ejection pattern refers to the direction your rifle sends its spent casings. Depending on the direction your casings go, your rifle may need some adjustments to improve its performance and reliability. Here’s what you should know.

Measuring AR-15 Ejection Patterns

The ejection pattern is the direction your rifle is sending its spent cases.

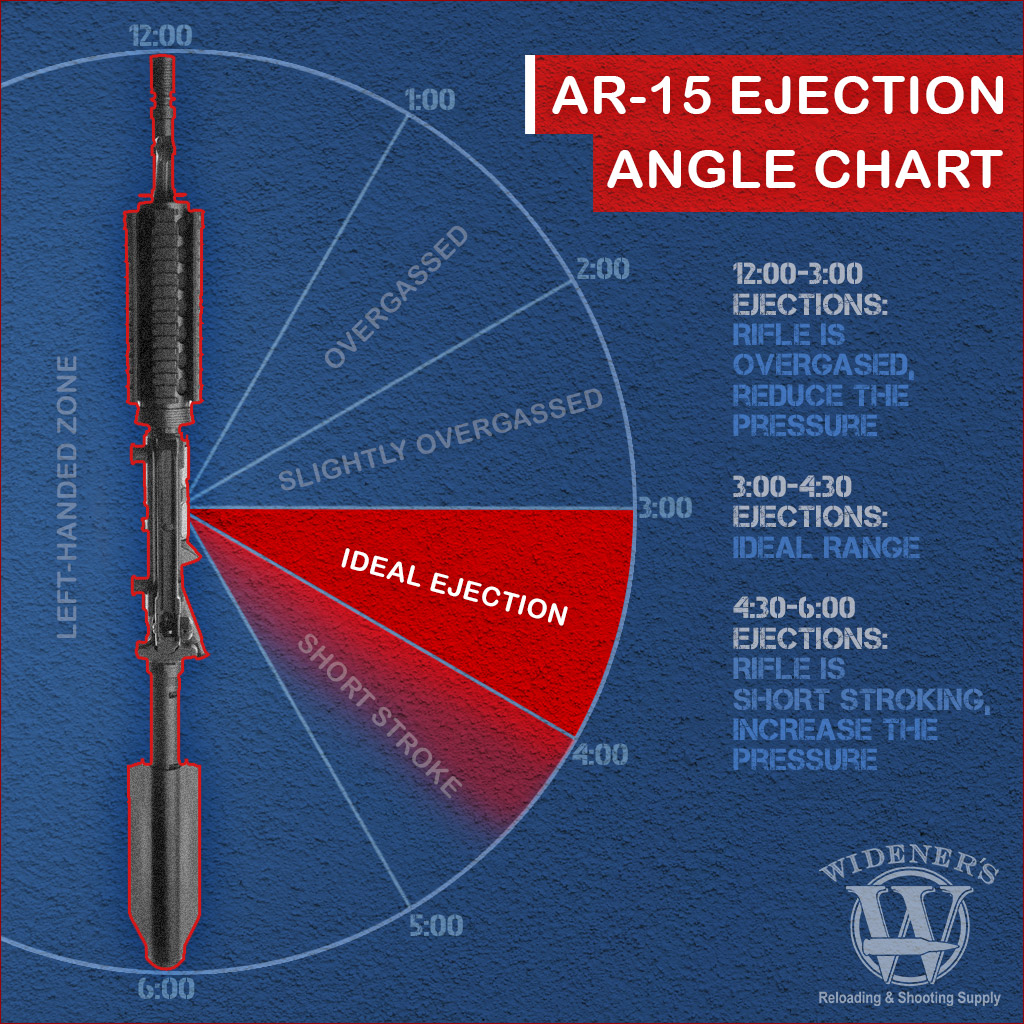

We measure ejection patterns like a clock’s face. The ejection port is at the center of the face and the stock points to 6:00. Conventional wisdom says the spent cases should ideally eject somewhere between 3:00 and 4:30. Still, some will eject between 12:00 and 3:00. In contrast, others come out between 4:30 and 6:00.

Rifles with ejector ports on the right-hand side can’t eject between the 6:00 and 12:00 positions. So if you see spent casings in this area, you know it likely bounced off something (like a wall or shooter on your right!) and landed in those positions.

Why Do These Ejection Patterns Matter?

Let’s keep in mind the adage that the first step in problem-solving is to ensure there is a problem. Many shooters do not concern themselves with where their cases eject unless the hot brass starts landing on them. Then they look for a solution. Otherwise, they leave well enough alone.

And while you shouldn’t get carried away with fine-tuning an AR-15’s ejection pattern, seasoned professional shooters agree there are benefits to observing them. Namely, diagnosing failures in the rifle’s components.

What Do Ejection Patterns Reveal About Your AR-15?

As you can see from the illustration below, the ideal ejector pattern begins around 3:00 on the clock face and runs to 4:30. But what about the other two patterns? 12:00 to 3:00 (Over-gassed) and 4:30 to 6:00 (Short Stroke). What do they mean to the user?

AR-15 Ejection Patterns

AR-15 ejection patterns are an indication of your rifle’s overall health and operational performance.

There are a lot of variables that go into diagnosing an ejection issue. The cycling speed of the bolt can affect the direction the brass is being sent. Assuming of course, that you’re shooting brass at all. If you shoot a lot of steel-case rounds, your extractor tension and ejector strength can also be a factor. Be sure not to ignore the rifle’s recoil impulse. If the rifle feels like it’s beating you up when you fire it, and it’s slinging brass at 12:00, you may need to adjust your buffer spring weight to better match your ammo.

12:00 to 3:00: Over-Gassing

Over-gassing symptoms can include:

- Ejection issues

- Low round velocity

- Feeding issues

- Excessive recoil.

Changing your magazine or ammo will sometimes fix the problem, but check out the gas system if that doesn’t help. ARs use a cyclical system to create pressure in the chamber. If any part of the cycle has too much pressure, it can disrupt the timing, causing several possible issues.

The gas block controls gas pressure in the AR-15. The explosive reaction of firing a round creates the pressure that travels down the barrel to the gas block. There, it’s collected and redirected to the upper receiver and bolt carrier group. That’s where it helps create the force that ejects the case and loads the next round.

Adjusting the gas pressure would be a simple fix – except most rifles come from the factory with single-setting gas blocks. However, adjustable gas blocks are readily available, and you can easily buy one and replace the stock single-setting block.

An adjustable gas block allows you to get the ideal pressure setting for better timing, gives you less carbon build-up, and prevents excessive wear. Better still, it should also result in a 12:00 to 3:00 ejection pattern.

4:30 to 6:00: Short Stroking

If your AR-15 starts ejecting cases at 135 to 180 degrees (4:30 to 6:00 on the clock face), this is probably an indication of short stroking. You can look at short stroking as basically the opposite of over-gassing. When short stroking, the cases barely eject and almost fall straight down when they do.

Short stroking indicates insufficient gas pressure returning to the upper receiver and bolt carrier group. With an adjustable gas block, you can increase the pressure. Be aware that heavy buffers and springs are also common causes of short stroking. Changing to a lighter buffer or spring will allow the bolt and carrier to travel fully rearward during firing.

And let’s not forget the importance of a clean and well-lubricated AR-15 for its proper operation. Soot and debris are a by-product of using the rifle, and their accumulation can slow or restrict the movements in the bolt carrier group. Short stroking sometimes happens because the slots in the gas rings on the bolt are not staggered, or the gas tube is blocked.

Finally, make sure you are using the right ammunition. For example, short stroking may occur if you use lower-pressure .223 Remington loads when the rifle is set for 5.56x45mm NATO ammo.

Understanding AR-15 Ejection Patterns

If you pick up your brass, there’s a good chance you already know where your empty casings land.

Avoiding many of the common causes of ejection problems is as easy as completing basic gun maintenance. If your gun already runs the solution may be as simple as adjusting the gas pressure. Before you start cutting springs or permanently modifying your rifle, make sure to do the following:

- Keep your AR-15 clean and properly lubricated.

- Maintain the correct gas pressure.

- Use the right ammunition with a clean magazine.

- Use the optimal buffers and springs.

Your AR-15 will thank you with consistent service, a long, trouble-free life cycle, and an ideal ejection pattern.